A personal note.

Shortly after I finished design school I was working at a small design house in Montreal when someone from one of the local factories told me that the general manager of the place they worked wanted to meet me. It had come to his attention that there was a young tailor working right around the corner and they needed more tailors. I had known of Samuelsohn for a very long time so I was excited to be summoned. They offered me a job right away and I accepted and began a career in tailored clothing manufacturing.

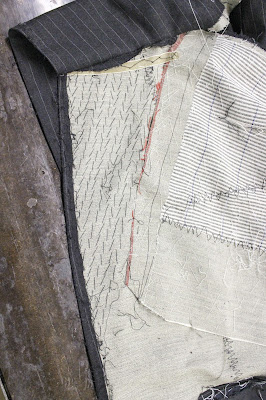

Samuelsohn is a company which places a high degree of importance on quality so I learned a lot about the mechanization and industrialization of traditional tailoring techniques with which I was already familiar, but never did I see an engineer doing time studies or hear discussions about costs or yields or output. After some time with the company my mentor told me that there was another company which needed someone like me. I didn't want to leave but he told me that I had a good understanding of how to do things well, but no idea how to do things efficiently and inexpensively, and that I should go work for a variety of companies and learn the different facets of the industry. Learn how to manufacture garments offshore. Learn how to forecast fabric and trim requirements. All sorts of things. He told me I wouldn't be ready to settle until I was into my forties. So armed with this advice I left Samuelsohn to go work for an importer, and then a few companies after that. On my last day a member of the Samuelsohn family told me that I would be back some day, that this was my home and my family.

Fast forward about 15 years and I was approached to go work for HMX group, formerly known as Hartmarx, in Chicago. I would take over the Hart Schaffner & Marx brand and help revitalize it, but one of the carrots they dangled was the opportunity to do some work with, and then perhaps some day take over as well, our sister company Hickey Freeman. Hickey Freeman is a factory that does some beautiful garments, mostly full-canvas like Samuelsohn, and I was lucky to work with that factory and with another mentor who was there at the time, Paul Farrington. At one point Hickey Freeman was sold, interestingly enough, to Samuelsohn, which was a huge disappointment to me. Some time later I was approached about helping to turn around another struggling company in the south, so I and two other colleagues ade plans to go south and fix the struggling company.

The company in question had been forced in to bankruptcy and had been producing very low cost and low quality garments. Our job was to redesign all the product, redesign the factory so that they could produce a better quality garment, teach existing staff how to do it, and hire other new staff and train them. A year and a half later we have gone from 210 employees to well over 300, we have made major strides in the quality, fit and appearance of the garments being produced, and were recently honored with an award given by a magazine which is hugely popular n the south known as Garden and Gun. There are still challenges which exist in terms of getting everyone up to full efficiency so the factory can meet the huge increase in demand, and some tweaks to the fit now that we see full production runs instead of just samples, but I feel like the bulk of the heavy lifting has been done.

So now I have a chance to "go home". I will be joining (or re-joining) the Luxury Mens Apparel Group, the company which owns Samuelsohn and Hickey Freeman in the new year, going back to work with a lot of the same people I have worked with over the years, plus a lot of new and fantastic ones. I will spend some time in Montreal, at Samuelsohn, before settling in Rochester at the Hickey Freeman factory. And now that I have reached those dreaded forties I am hoping it's now time to settle down. So Jack and George were both right, those twenty years ago.